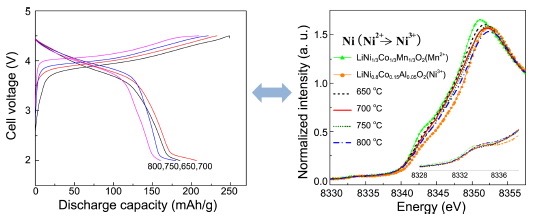

Preparation and Cyclic Performance of Li1.2(Fe0.16Mn0.32Ni0.32)O2 Layered Cathode Material by the Mixed Hydroxide Method

Vol. 34, No. 7, pp. 1995-2000, Jul. 2013

10.5012/bkcs.2013.34.7.1995

10.5012/bkcs.2013.34.7.1995

Tumbnail

Abstract

Statistics

Cumulative Counts from November, 2022

Multiple requests among the same browser session are counted as one view. If you mouse over a chart, the values of data points will be shown.

Multiple requests among the same browser session are counted as one view. If you mouse over a chart, the values of data points will be shown.

|

|

Cite this article

[IEEE Style]

K. Karthikeyan, K. W. Nam, E. Y. Hu, X. Q. Yang, Y. S. Lee, "Preparation and Cyclic Performance of Li1.2(Fe0.16Mn0.32Ni0.32)O2 Layered Cathode Material by the Mixed Hydroxide Method," Bulletin of the Korean Chemical Society, vol. 34, no. 7, pp. 1995-2000, 2013. DOI: 10.5012/bkcs.2013.34.7.1995.

[ACM Style]

K. Karthikeyan, K. W. Nam, E. Y. Hu, X. Q. Yang, and Y. S. Lee. 2013. Preparation and Cyclic Performance of Li1.2(Fe0.16Mn0.32Ni0.32)O2 Layered Cathode Material by the Mixed Hydroxide Method. Bulletin of the Korean Chemical Society, 34, 7, (2013), 1995-2000. DOI: 10.5012/bkcs.2013.34.7.1995.